From tape and glue to Velcro and stickers, adhesives are all around us, yet some things seem to stick way better than others. There is actually some fascinating science behind creating surfaces that stay slick rather than sticky. The people at Trecora explain that materials engineers use special coatings and ingredients to reduce adhesion and friction, so things glide smoothly instead of holding fast. From slippery suitcases to stain-proof clothing and ice-shedding planes, polymeric coverings like polyethylene wax along with clever structural designs enable all kinds of handy non-stick inventions.

Repellent Shields

One way to foil sticky messes is by guarding surfaces with a repellent shield. Materials that resist water, oils, and other contaminants prevent buildup and residue that leads to sticking and staining. Grease-proof barriers like those used on some food packaging make surfaces slippery so food won’t adhere. Non-stick cookware applies a smooth polymeric coating such as polytetrafluoroethylene (PTFE) to prevent burning and sticking. Water beads up and glides off hydrophobic coatings with tightly packed molecular structures that repel liquid penetration. Materials engineered explicitly not to mesh with sticky substances produce an effortless release effect.

Shape Stratagems

Along with specialized materials, strategic surface shapes and textures minimize adhesion. The lotus leaf has tiny nano-sized bumps that reduce contact area and make water, dirt and particles roll right off the leaf in an adaptational effect studied by bio-inspired innovators. Structured polymer coatings mimic this self-cleaning lotus ability for stain-proof clothes and dirt-shedding paints. Manufactured microscopic topography modeled after rice leaves, butterfly wings and shark skin resists sticky build up. Even large-scale surface patterns foil unwanted adhesion: dimpling on golf balls decreases air resistance and friction, while ridges lift sticky ice as planes take off. Using physics and smart configurations beats sticking with no need for temporary treatments or sprays.

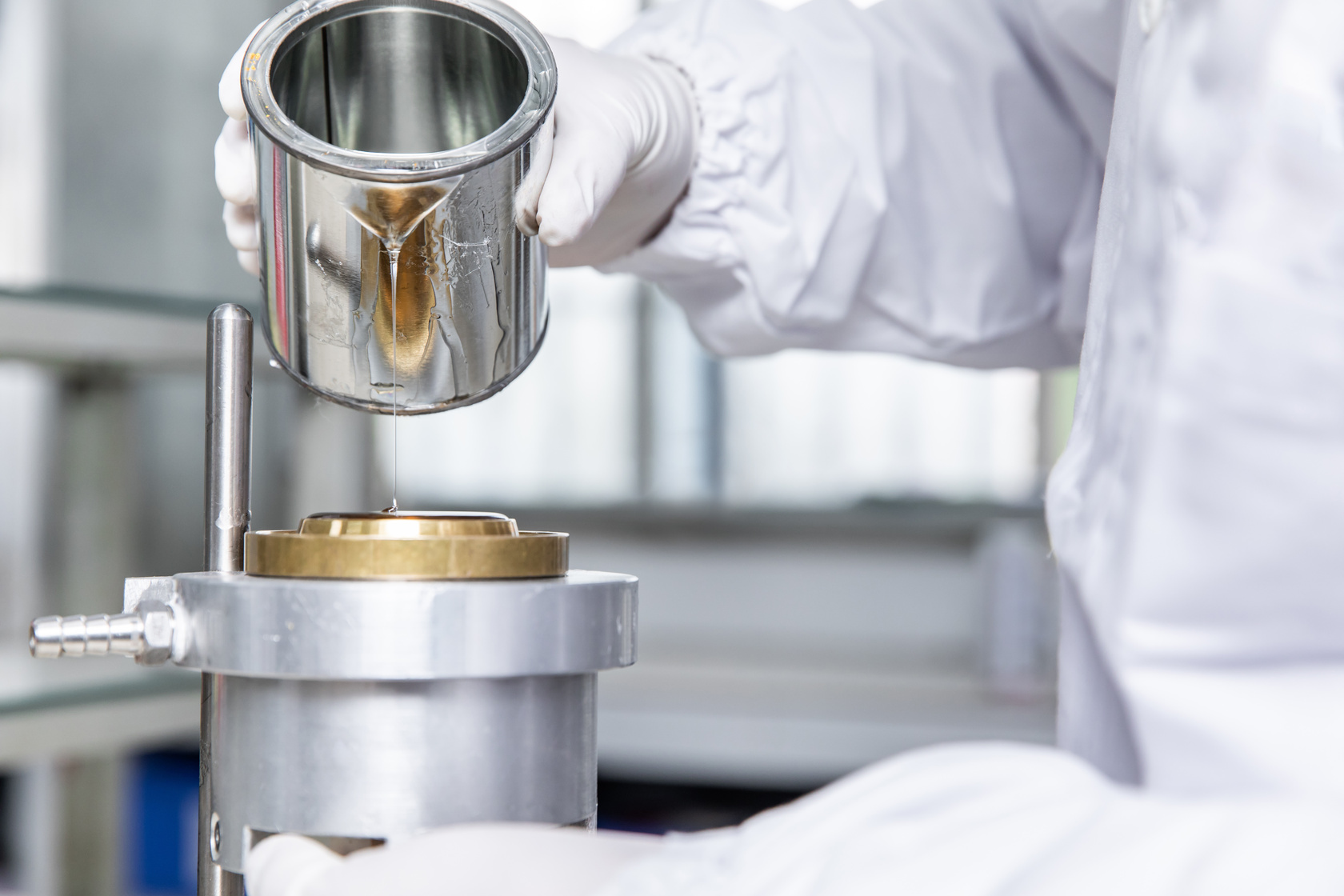

Dry Lubricant Compounds

While oils facilitate sliding in liquid form, dry lubricant compounds work by plate-like additives sliding past each other, like a deck of cards being shuffled. Powdered graphite, boron nitride, molybdenum disulfide and tungsten disulfide minerals physically separate surfaces with tiny layers. Hexagonal boron nitride nanosheets enhance plastics and polymers for slippery fabrics and coatings. Polyethylene wax applied to metals, ceramic and composites fills in cracks and defects, acting as a dry lubricant to prevent corrosion and improve wear resistance through friction reduction. Microscopically slippery materials smooth the way for all kinds of applications where wet oils and greases collect gunk and cause problems.

Clever Design Interventions

Finally, sticking woes fade away with intelligently devised designs that stop snags before they start. Zipper teeth engineered at a steeper angle glide more easily over the ridges. Rounded safety backpack zipper catches prevent fabric, strings and loose threads from getting caught and stuck in the teeth. Non-stick cabinet hinges, handles and latches apply slippery polymers, so drawers and doors operate freely without sticking or catching. An ingeniously placed notch in tape rolls lets the end tuck away so it won’t stick to the next loop round. Tiny design tweaks to leverage physics and materials science eliminate frustration when adhesives unite unintended surfaces.

Conclusion

A collection of clever tricks resists sticky messes thanks to the science of material repellency, bio-inspired micro-structuring, dry lubricating compounds and thoughtful design edits. Slick shields of polymers, microscopic bump texturing and dry film lubricants facilitate smooth sliding and release. Sticky problems are dissolved by strategically managing surface contact and interactions at macro and microscopic scales. With physics guiding material selection and part geometries, engineers conjure up all kinds of ingenious solutions to life’s little sticking points. The result is adhesive-free surfaces that shed water, release dirt, resist corrosion and always slide effortlessly.